Grease Trap Perth and interceptors are effective grease management solutions – but only if they’re properly maintained. Without regular emptying and cleaning, accumulated grease waste can solidify, creating blockages and reducing trapping capacity.

This can lead to costly repairs for the sewer system, disruptions for staff and customers, fines for non-compliance with regulations and environmental harm. This is why it’s important to follow EPA guidelines for grease trap requirements.

A grease trap is a plumbing device that captures fats, cooking oils and grease (FOG) from your kitchen drain and prevents them from entering your sewer system. These devices are often installed in restaurants and commercial kitchens but can also be found in some residences as well. They can be either internal or external and come in a variety of shapes, sizes and designs. There are many DIY tutorials online that provide step-by-step instructions for installing a grease trap yourself but it is recommended to use a licensed plumber. This will ensure your grease interceptor is properly installed and meets any local regulations or manufacturer guidelines.

If not cleaned regularly, the contents of your grease trap can overflow into your kitchen and into the surrounding area. This can create a health and safety hazard as well as cause blockages in your kitchen drains. FOG is also a common cause of thousands of sanitary sewer overflows across the country every year.

Keeping your grease trap clean is therefore an important task in any restaurant, commercial kitchen or other foodservice establishment. Grease traps need to be emptied and pumped out regularly, usually at least once per week. The frequency will depend on the size of the trap, how much you cook and the number of people using your kitchen. A professional grease trap cleaning service provider will be able to help you determine the best schedule for your needs.

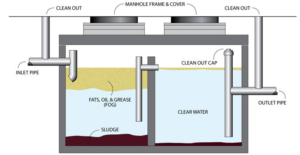

Your grease trap will usually consist of two chambers connected by a tube. The first chamber holds the grease, allowing it to solidify and eventually float to the top of the trap. Water and other non-greasy waste then passes into the second chamber where it is separated from the FOG and flows into the sewage system.

When the first chamber gets full, your grease interceptor will need to be emptied. This can be done through the outlet fitting and cap or through a separate manhole cover which is typically located around 18 inches away from the base of the trap.

There are a few different methods of pumping your grease trap but the most important factor is to make sure it is done regularly. You should find out what the pumping regulations are in your municipality and use a service provider that is familiar with these requirements. Some companies will simply remove the FOG from the trap and then return it to your kitchen while others will empty the entire trap, dry it out and then haul it away.

How Does a Grease Trap Work?

Many cities require grease traps for restaurants and other food preparation establishments to keep fats, oils and greases (FOG) out of sewer waste systems. Because FOG can block sewer pipes and lead to sanitary sewer overflows, which are a major health and safety risk, municipalities are often required to inspect these receptacles regularly. Grease traps, also known as grease interceptors, work by separating animal and vegetable fats from other kitchen wastewater. They consist of a receptacle with a baffle wall and a drain inlet and outlet. Most commercial kitchens use one or more of these receptacles, with smaller variations designed to connect individual sinks and larger ones installed to serve entire facilities.

When kitchen wastewater flows into the grease trap, it passes through a flow rate controller and into an inlet pipe. The receptacle then slows the water down significantly, which separates the wastewater into layers. Solids settle on the bottom, wastewater in the middle and FOG on top. The cooled and solidified FOG can then be removed manually or automatically using a pump, skimming device or other grease removal method.

During the course of operation, FOG can build up in the receptacle until it is full or overflows. As a result, it is important to clean the grease trap on a regular basis, typically every 3 months or more frequently. A dirty trap can create a foul odor and overflows that are costly and hazardous to customers and employees. FOG in the sewer system can also cause clogs, backups and other issues.

The frequency of cleaning a grease trap varies depending on how much your establishment produces. During busy seasons when more waste is washed down the drains, you will likely need to clean the trap more often to prevent clogging and avoid frequent overflows.

Once the trap is cleaned, it should be pumped and the captured grease and other materials should be disposed of properly. Be sure to partner with a service provider that provides safe and responsible disposal of the grease, as illegally dumping the material can be fined by the city.

How Do I Clean a Grease Trap?

The best way to keep your grease trap in good working condition is to clean it on a regular basis. Depending on how much your restaurant uses it, your trap should be cleaned every 1-3 months to prevent buildup. Keeping your grease trap clean can help you avoid plumbing issues, unpleasant odors, and expensive sewer cleanup services.

Begin by turning off all water sources that drain into the grease trap. Next, use a heavy-duty scraper to remove solid waste from the trap. Be sure to dispose of this waste properly according to local regulations. Once the trap is empty, flush it with a high-pressure hose to wash away any remaining debris.

Once the trap is fully cleaned, it’s important to test it for proper operation. A grease trap must be able to separate wastewater from FOGs. If the FOGs are not separated properly, they can flow downstream into your business and clog pipes or the municipal sewage system, resulting in costly clean up and repair.

Grease traps must also be inspected and pumped out on a regular basis. If your trap is leaking FOGs into the surrounding environment, or if you’re experiencing frequent odors, it may be time to invest in a new one.

Another sign that your grease trap isn’t working correctly is when the wastewater isn’t flowing freely through it. If this is happening, it’s important to contact a professional grease trap cleaning service right away.

Many companies offer a full range of professional grease trap maintenance and cleaning services. Expert technicians will visit your site and perform a thorough cleaning using specialized equipment, ensuring that even hard-to-reach areas are clean. They’ll also provide you with detailed reports and a history of your grease trap cleanings, so you can stay on top of your maintenance schedule. Then, when the time comes, you’ll be able to show your municipality proof that your grease traps are being cleaned regularly. Using a professional grease trap cleaning service can also help you avoid the hefty fines that are often associated with unclean or over-filled grease traps.

What Equipment Do I Need to Clean a Grease Trap?

When a grease trap needs to be cleaned, it is important that the proper equipment is used. Using the wrong equipment can result in costly repairs and/or fines. It is also important that the grease is disposed of properly. Failure to do so can lead to health code violations and put animals, fish, and humans at risk. If a business does not have the proper equipment to handle the disposal of grease, it may be better to hire a professional commercial plumber.

First, the grease trap must be drained. This can be done by using a bucket or small pump to remove the water from the bottom of the trap. Once this has been completed, the waste can be removed from the trap and placed in a water-tight garbage bag for disposal. It is recommended that you use a face mask during this process. Next, the trap must be inspected. It is a good idea to take photos or draw a diagram of the trap’s different parts before you begin. This will help you remember where each part goes when it comes time to re-install them after cleaning.

The grease trap must then be scoured with a steel pot scrubber and soapy water to remove any remaining solidified waste. It is also a good idea to flush the trap with clean water. This will eliminate any bad odors and help to keep any material that was knocked free but not yet removed from accumulating quickly. Once the trap is cleaned, it should be emptied and the contents disposed of by a licensed grease hauler.

While cleaning a grease trap can seem like a messy and unpleasant task, it is a necessary one for any commercial kitchen. Using the proper equipment will ensure that the trap is clean and functioning properly. If you are unsure of how to properly clean and dispose of your grease trap, it is always best to call a professional commercial plumber. They will be able to provide you with the services you need to meet your FOG management regulations and avoid fines or shutting down your business.